What is CatalystMS?

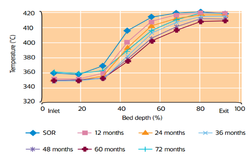

CatalystMS provided by Fitiri works with CatTracker® and is used for monitoring catalyst performance in process plants. Data collected over a period are analyzed instantaneously and the remaining life of the catalyst can be calculated. This helps in making critical decisions and closely monitoring design defects and other related issues. This information is crucial for both the catalyst supplier and the plant manager.

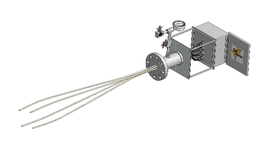

About CatTracker

|

Patented Cat Tracker Temperature MeasurementCatalystMS uses Daily Thermetrics’ patented CatTracker temperature measurement technology.

|

CatalystMS Features & Application

|